Steel american iron and steel institute 1 see aisi s fabrication guidlines for cold bending thk 6061 t6.

Bending 125 aluminum sheet.

Many times when people say oh yeah i bend aluminum all the time they are talking about aluminum that is 3003 and its tensile is half that of 5754.

Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend.

The other thing to remember is that in terms of sheet metal equipment the force required goes up with the square of the increase in thickness.

Aluminum sheet metal comes in a variety of thicknesses and weights in many different grades.

This will give you a nice bend.

Which aluminum alloy bends the best is a a common question customers want the answer to.

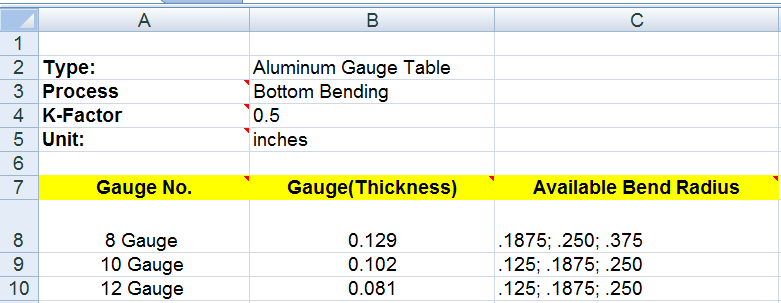

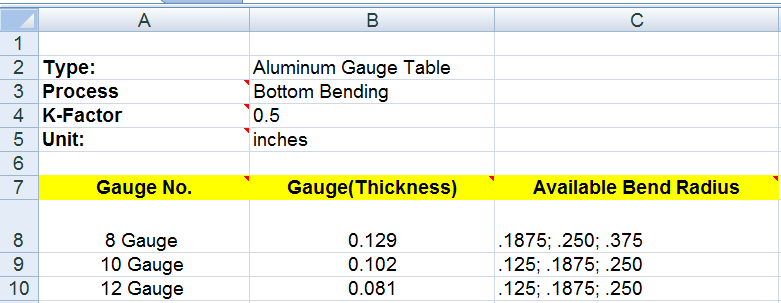

Your 125 thickness will need a radius of 187 to 375 on the inside of the bend.

Aluminum where necessary 5052 h32 may be bent to 1t and 6061 t6 to 1 1 2t.

If bending along the grain you want closer to the bigger numbers and across you can bend to a smaller radius.

With the aid of a straight edge and a sharp knife score both sides of the aluminium sheet.

Place the fracture line over the edge of a table and bend the overhang slightly downwards.

Some other alloys of aluminum are softer.

This weakens the aluminium and creates a fracture line.

Die and a 0 03 in.

We were working with 0 125 in thick 6061 t6 aluminum but we were experiencing cracking problems so we switched to 1100 o aluminum with a specified tensile strength of just 13 000 psi.

To define the bend region and reduce the force required to bend a part out of sheet metal down to something you can handle without a brake press slots can be cut at the bending line to.

Bending is a delicate and demanding process most of the time and common fabricating processes require a degree of formability that make your choice of proper alloy critical.

Ryerson offers heat treatable aluminum sheet grades like the popular 6061 aluminum alloy that can be used for commercial applications that require strength corrosion resistance and machinability as well as non heat treatable grades when formability and weldability are priorities.

Grain direction bend line should go across the grain for the best bend having said that a typical sharp 90 bend on a piece of 1 8 aluminum sheet should be a minimum 1 8 inside radius use either 3003 or 5052 ideally the bend line should go across the grain.

If you search for aluminium bend radius you will find that 6061 t6 should be bent with a minimum bend radius of 1 1 2 to 3 times the sheet thickness.

I have a 0 984 in.

In high purity forms aluminum is soft and ductile.

Material bend radii and minimum bend size charts please note.

In this post we ll explain it to you.