Grain direction bend line should go across the grain for the best bend having said that a typical sharp 90 bend on a piece of 1 8 aluminum sheet should be a minimum 1 8 inside radius use either 3003 or 5052 ideally the bend line should go across the grain.

Bending aluminum sheet with the grain.

Bending sheet metal can be useful if it s used to build different shapes and different products.

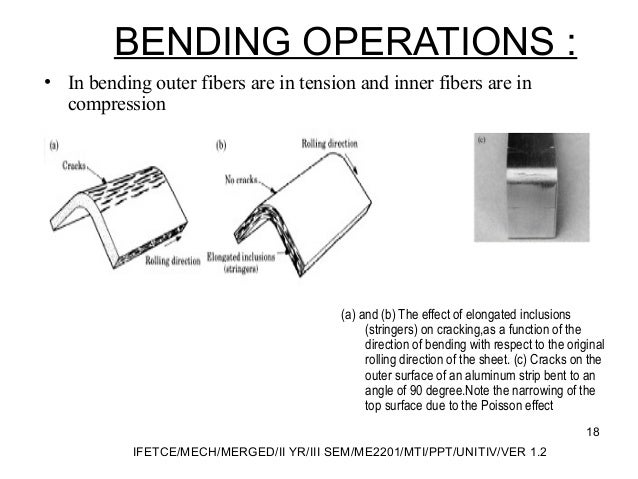

Minimum inside bend radius is also larger when bending with the grain longitudinal than across the grain transverse.

The harder and thicker the metal the greater the minimum bend radius.

Grain direction also plays into the amount of springback you can expect.

Bending the sheet metal longitudinally with the grain allows those grains to separate at the grain boundaries.

Local sheet metal shop not an aircraft shop experienced cracking on folding up a simple bracket.

In this post we ll explain it to you.

To predict the material s behavior accurately during bending especially at the press brake you need to accommodate for the grain direction.

Understand different metals have different minimum bend radius to thickness ratios.

Bending is a delicate and demanding process most of the time and common fabricating processes require a degree of formability that make your choice of proper alloy critical.

The grain direction is established during the metal rolling process.

Which aluminum alloy bends the best is a a common question customers want the answer to.

In particular we will take an in depth look at the theory making a.

Bending with the grain gives a different result than bending against it.

This will give you a nice bend.

In high purity forms aluminum is soft and ductile.

You must pay careful attention to grain or rolling direction when bending high strength metals especially when trying to achieve a small inside bend radius.

When bending high strength materials such as.

This is because sharper or tighter bends can be made across the grain without cracking.

In addition the grain direction needs to be considered when the bend radius is less than twice the thickness depending on the material and its hardness.

A metal s grain direction is usually only a factor when bending however.